Tech talk: How Vespa Automatic Transmissions Work

By Maxwell Materne

Just about once a day I surprise someone by saying that all new Vespas are automatic. Twist and go, nothing to it, easiest thing in the world to ride. Inevitably it’s followed by the question of, “how does that work?” It’s really quite simple and ingenious; first let’s get an understanding of some of the principles behind gearing.

Gear Ratios

A vehicle’s gear ratio is a huge part of its driving characteristics. Let’s go back to your first 10 speed bicycle. Each click through the gears changed the speed you were traveling while keeping your legs moving at the same rate.

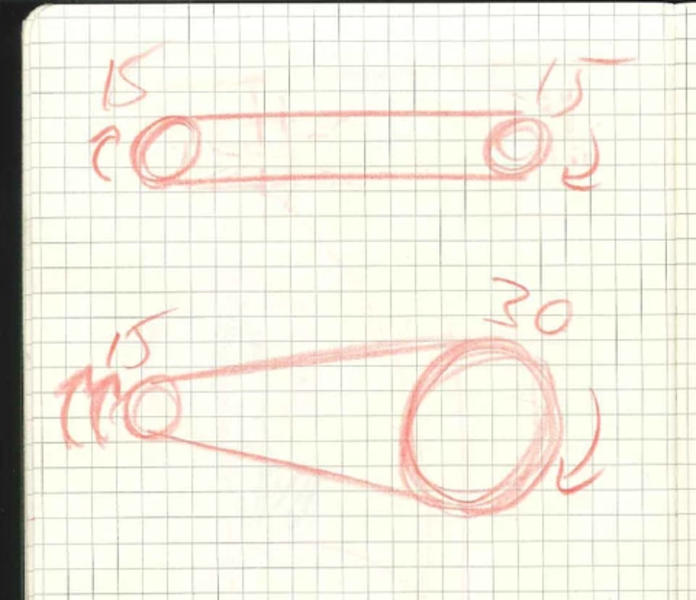

If you were to have a 15 tooth front (driving) sprocket and 15 tooth rear (driven) sprocket connected by a chain, each sprocket would be moving at the same speed. With a 15 tooth front and a 30 tooth rear every revolution you make with you legs only equates to a half a rotation on the rear sprocket. This gearing ratio would be an easy way to get the bicycle moving but with higher speeds you would have to increase the speed of your pedaling or decrease the gear ratio to something like our 15 to 15 tooth set-up (1:1 gear ratio). This is the basic principle of how transmissions use gear ratios to convert an engine’s small RPM range to a larger range of speeds.

CVT

Automatic scooters use a continuously variable transmission (CVT) this allows a smooth, stepless alternation of gear ratios. How the transmission smoothly transitions through gear ratios from a small front and large rear (for slow speed) to a large front and small rear (for high speeds) is done using centrifugal force, cones, a “v” shaped belt and springs.

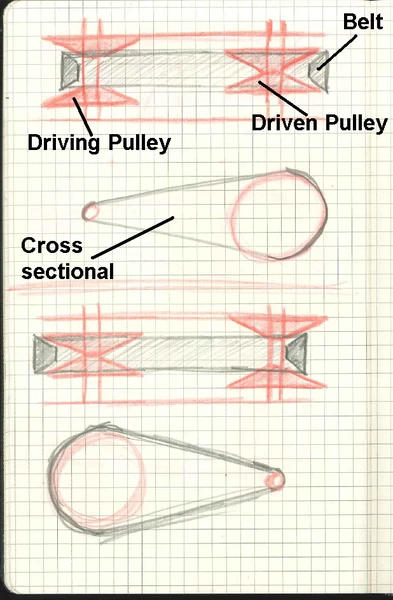

On one side of the transmission (input side) two inward facing cones set on splines of the crankshaft have a “v” shaped belt wedged between them. The belt is then fed into a similar two cone system on the output side. By variating the distance of the inward facing cones to each other the ride height of belt on the cones will change. Because the belt does not vary in size but the cones vary in distance, the ratios change on a sliding scale.

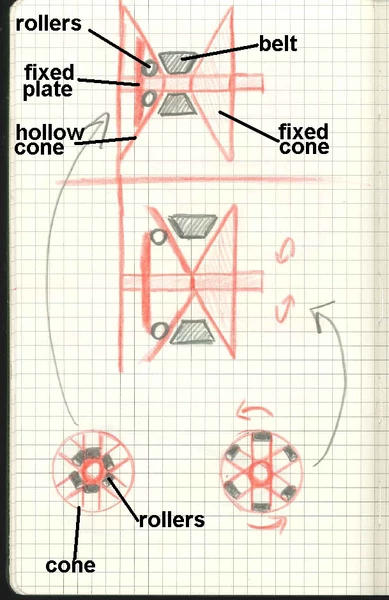

Let me explain how the driving pulley (set of inward facing cones) works. The pulley is connected directly to the output of the crankshaft. This means that the up and down motion of the piston is converted to circular motion and put directly to this pulley. The outside cone of the pulley is bolted in place on the crankshaft while the inside cone expands on its own to become closer to the other cone. This inner cone has 3 major components: hollow cone, roller kit and fixed backing plate. The fixed backing plate is held in one spot while rollers between it and the hollow cone are roller outward with centrifugal force to push the hollow cone forward and vary the distance of the two cones.

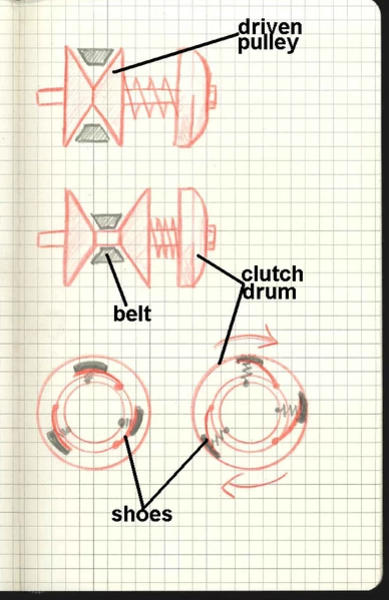

Now that we know how the driving pulley variates its cone to cone distance, the rear driven pulley is even easier. The rear cones are pushed together by a spring. The force of the spring is overcome by the belt being pulled deeper between the cones once the driving pulley starts to expand. The only thing that complicates the driven pulley is the clutch, which allows the bike to idle and not lurch forward.

Clutch

The clutch is located on the outside of the driven pulley and its principle is quite simple. It consists of shoes (same as brake pads), springs and a drum. The drum is fixed to the driven shaft powering the rear wheel and the shoes are connected via the springs to the driven pulley that is free spinning around the driven shaft. When the speed of the driven pulley produces enough centrifugal force for the shoes to overpower the springs (just off idle) the shoes grab hold of the drum as begin to spin the driven shaft. In other words, the drum and shoes do not make contact until you are gassing the throttle.

Recap

When you hit the start button on your brand new Vespa the “suck, squish, bang, blow” sequence of your engine starts turning the crankshaft. This spins your driving pulley, belt and driven pulley. Once you give the bike some throttle the clutch engages and the rear wheel starts spinning. The more throttle you give, the farther the rollers in the driving pulley roll out making the 2 driving cones come closer together and the belt rides up the cones. Because of this the belt pulls farther between the cones of the driven pulley.

There you have it! Continuously variating transmission that is using a small engine RPM range to produce a wide array of speeds.